Protective ventilation system SBL 30 Comfort Comfort

The newly developed SBL30 Comfort meets all the requirements of BG Information 581 and DGUV Information 201-004. Like all other Wölfle systems, the system is characterized by a high level of operational safety, optimal functional control, low operating costs and simple operation.

During development we focused on the essentials in order to offer the machine operator the best possible protection at a reasonable price.

Like the SBL30 Premium, this system was developed to protect the driver from toxic gases in landfills, composting plants, during renovation work or when disposing of military waste. Of course, it also protects against suspended matter such as asbestos, spores, fungi and bacteria thanks to the H13 suspended matter filter and the upstream cyclone pre-separator and is of course also suitable for odor filtering.

operation area

Typical areas of application are construction sites with a lot of dust or even asbestos, remediation areas with contaminated sites, landfills, composting and sorting plants and all other work areas contaminated with pollutants. With our system, your machine operator is optimally protected from toxic gases, pollutants and odors.

Technical data

Basic device

- Dimensions in mm: 425 x 480 x 320 (L x W x H)

- Hose connections: 50 mm

- Weight: approx. 19 kg without filter

- Voltage: 24V with voltage converter also 12V available

- Housing construction: Painted metal housing with KTL corrosion protection

- Blower: Three-stage radial blower

- Control panel: Three-stage fan switch, LED pressure display, filter detection

- Warning light: Green warning light with 7W bulb

- Cable set: media and UV resistant

- Air hose: Flexflyte Super

- Air volume: Max. 120 m³/h

- Constant air flow rate: 35m³/h

- Current consumption: < 6 A at 24 V, < 12 A at 12 V with filter inserted

- Filter stage 1: Air filter pre-separator with cyclone and fine dust filter

- Filter level 2: HEPA filter H13 (DIN EN 1822)

- Filter level 3: activated carbon ABEK (DIN EN 14387 and DIN EN 12941)

- Removal efficiency: > 98%

- Recirculating air filter device

- Dimensions in mm: 295 x 230 x 175 (L x W x H)

- Weight: 4.5 kg without filter

- Housing construction: Powder-coated metal housing

- Blower: Single-stage centrifugal blower

- Filter: H13 (DIN EN 1822)

Your added value

- Compactly built for use on small construction machines

- Insensitive electronics and controls

- Existing heating/air conditioning systems are operated with pure air - increasing their service life

- Tested according to BGI581, EN15695 Cat. 1-4 and DGUV Information 201-004

- Tested filters according to EN14387 and 12941

- Triple, extremely secure sealing concept

- Electronic monitoring of the filter and the cabin pressure - high level of safety

- Very low and constant air flow rate of 35m³/h - lower operating costs

- Long filter life thanks to H13 suspended matter filter with large filter area

- Long filter service life and protection of the fan thanks to a separation efficiency of over 98% thanks to the cyclone with G4 particle filter in front of the actual filter

- Automatic renewal of the seal when changing the filter as it is attached to the filter

- Affordable filters due to the perfected design of the system

- Maintenance-free thanks to sealless housing design

- Can also be used as a pure dust filter system by simply changing the filter

- No voltage doubler required, system available in 12 V and 24 V

- No additional relays necessary due to simple connection to the vehicle electrical system

- High tightness of the system - low fresh air volume / longer filter life / low noise / guaranteed safety

- Robust stainless steel housing - painted

- Intrinsically safe thanks to blowing arrangement - high-performance blower (3 stages)

- Compact and lightweight system - easy installation

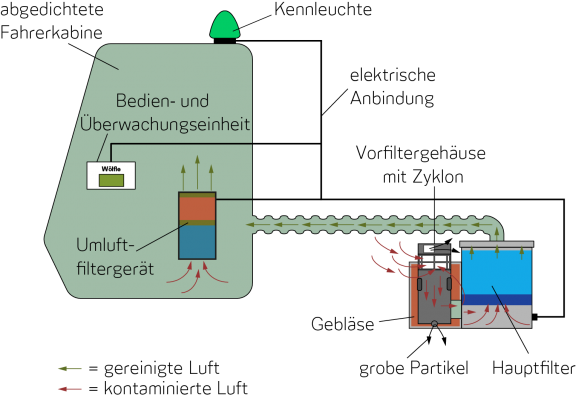

functionality

The contaminated air is sucked in via the pre-filter housing. The cyclone in the upper area separates the coarse dust particles. There is a G4 filter element in the pre-filter housing, which filters fine dust particles. The cleaned air flows via the fan to the main filter. When using the combination filter in its first filter stage (filter class H13), suspended matter is removed via the main filter. In its second filter stage, the gaseous pollutants are then absorbed in the activated carbon.

The cleaned air flows into the driver's cab via the air hose. The recirculating air filter device circulates the air in the cabin.

When the driver gets in and out, contaminated air may be introduced into the driver's cab. After the cabin is closed, these contaminants are removed during operation of the recirculating air filter system.

The system is put into operation and monitored via the control panel.

The beacon signals to outside personnel that the system is functioning properly.

filter

- Cyclone pre-separator

- G4 filter element

- HEPA filter H13 / H14

- Activated carbon / HEPA filter

- Recirculating air filter H14

credentials

Wölfle Service GmbH

Michael Schäfer

Service and Sales

Wölfle Service GmbH

M +49 (0) 16098422595

Wölfle SAS

Didier Heinrich

Dipl.-Ing. (FH)

Key-Account-Manager

Sales in France

T +33-658-696359