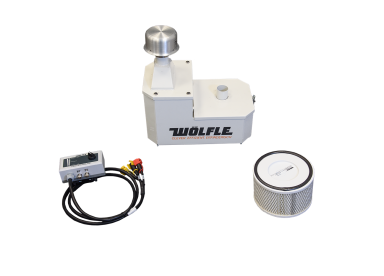

Dust filter system SF120

The Wölfle dust filter system is an effective and cost-effective solution for retrofitting your machines for dusty applications such as demolition work, road and tunnel construction, agriculture, etc. The system removes suspended matter such as dust particles, soot, asbestos, spores, fungi and bacteria through the H13 suspended matter filter and the upstream cyclone pre-separator.

In order to adequately protect the driver, in many cases you do not need a protective ventilation system, but are excellently protected against contaminated air with our dust filter system. The prerequisite is that the contamination is “only” suspended matter. Our system also makes work easier for your air conditioning system and generally ensures better value retention for your machine.

operation area

During dust-intensive operations, the driver of a work machine is exposed to fine dust that is hazardous to his health. Examples include applications in the demolition industry, in road and tunnel construction, in the mining industry and in agriculture. As an effective and cost-effective solution, the system itself can be retrofitted onto excavators, wheel loaders, telehandlers, forklifts or trucks, for example.

Technical data

- Dimensions in mm: 465 x 270 x 490 (L x W x H)

- Hose connections: 50 mm

- Weight: approx. 10.50 kg without filter

- Voltage: 24V with voltage converter also 12V available

- Housing construction: Painted metal housing with KTL corrosion protection

- Blower: Stepless, brushless high performance blower

- Control panel: Three-stage fan switch, LED pressure display

- Warning light: Green warning light with 7W bulb

- Cable set: media and UV resistant

- Air hose: Highly flexible thermoplastic hose

- Air volume: Max. 120 m³/h

- Current consumption: Max. 5 A at 24 V, 10 A at 12 V with filter inserted

- Filter stage 1: cyclone - air filter pre-separator

- Filter level 2: Minipleat HEPA filter class H13 according to EN1822-2009

- Removal efficiency: 98% of all particles up to 5µ

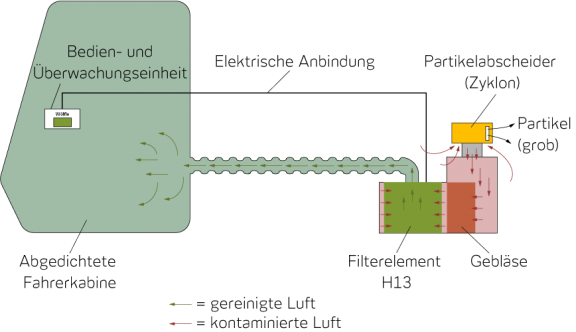

functionality

Contaminated air is sucked in via the air filter pre-separator.

Coarse particles are separated using a cyclone. The fan pushes the air into the filter housing. The contaminated air is filtered through a fine dust filter (class H13). The air cleaned in this way is now blown into the cabin via an air hose, if possible via the existing heating/air conditioning system.

The system is put into operation and monitored via the control panel.

Declaration of conformity SF 120

Your added value

- Degree of separation: 98% of all particles up to 5µ Example: asbestos

- Existing heating/air conditioning systems are operated with pure air - increasing their service life

- Very simple operation and optimal function monitoring with integrated pressure display

- Based on DGUV Information 201-004 and EN 15695 Cat. 1 to 3 (according to applicability)

- Inexpensive alternative to the protective ventilation system for pure dust operations

- Tested H13 dust filter with a very large filter area and pre-filtering via a multi-cyclone pre-separator for a long service life of the filter - lower operating costs

- Simple, quick filter change - no tools required

- Safe and easy handling thanks to the insensitive electronics and controls

- Existing air conditioning is operated with pure air - increases its service life

- Very simple operation and optimal function monitoring with integrated pressure display

- Intrinsically safe thanks to blowing arrangement - high-performance blower (3 stages)

- Compactly built and very suitable for use on smaller construction machines

- Vibration-optimized attachment thanks to special damper elements

filter

- Cyclone pre-separator

- HEPA filter H13/F7

credentials

Wölfle Service GmbH

Michael Schäfer

Service and Sales

Wölfle Service GmbH

M +49 (0) 16098422595

Wölfle SAS

Didier Heinrich

Dipl.-Ing. (FH)

Key-Account-Manager

Sales in France

T +33-658-696359